When organic material breaks down without access to oxygen (anaerobic conditions), biogas is formed. Some biogas is therefore formed by the breakdown of bottom sediments in lakes, in wetland areas (e.g. in marshy areas), and by the breakdown of fodder in the rumen of livestock. Biogas mostly consists of methane, CH4, carbon dioxide, CO2 , hydrogen sulfide, H2S and is saturated with water vapor (50-60% methane, and 40-50% carbon dioxide, ~1 vol % H2S). When these gases are released into the atmosphere, they contribute to intensifying the greenhouse effect. Converted to CO2 equivalents, methane has a 25 times stronger effect as a greenhouse gas than carbon dioxide.

In a biogas plant, organic waste is broken down and biogas is produced. Much of the biogas consists of methane, which can be used for energy purposes. In agriculture, manure is the most important substrate taken into a biogas plant. In addition, other substrates such as e.g. food waste and fish waste. This gives a greater gas yield than when using animal manure alone. The residue left after the biogas process is called bioresidue, and is used as fertiliser.

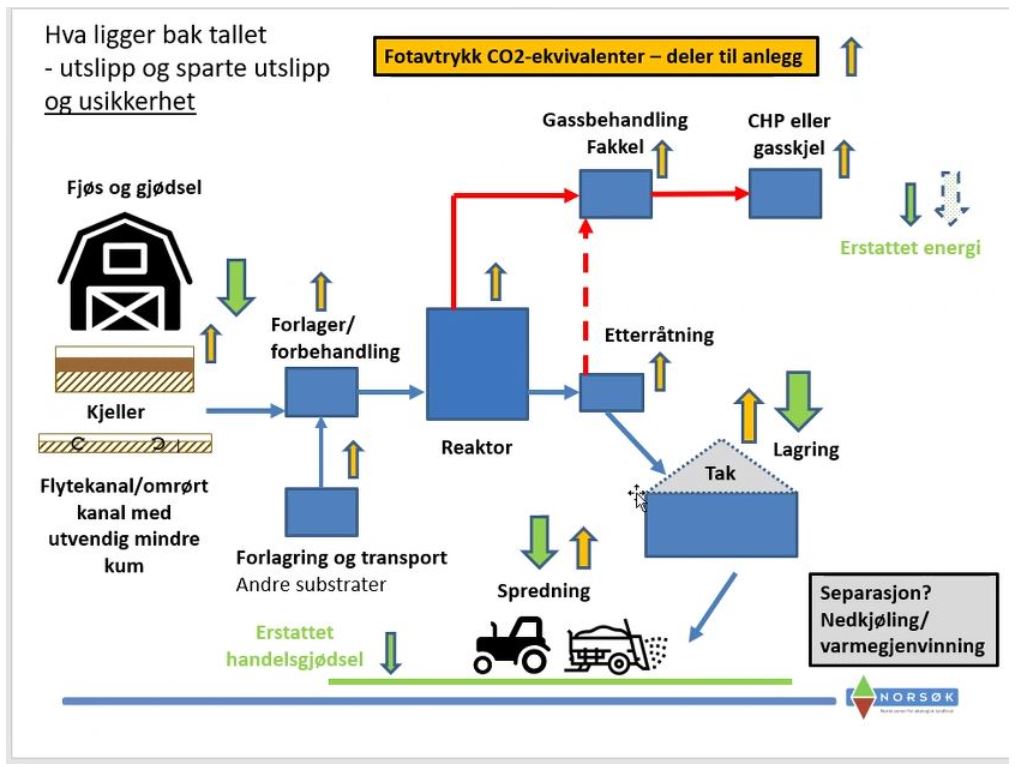

In its simplest form, a biogas plant consists of a pre-storage, where livestock manure is taken in and optionally mixed with other substrates, before it is pumped into the biogas reactor. In the reactor, microorganisms break down the organic material. The microorganisms that break down the organic material depend on a certain temperature in order to exist. The substrate must therefore be heated before the biogas process gets fully underway. The biogas produced in the reactor is taken out and directed to a gas storage. Methane is a flammable gas, and can be used to heat houses, to produce electricity, and as fuel for vehicles.

Substrate is pumped in at regular intervals throughout the day, and bioresidue is also regularly taken out and pumped to the final storage. The residence time for the substrate in the biogas reactor varies from plant to plant. The longer the residence time, the more biogas is produced. The length of stay can vary from 7-21 days, and some facilities operate with a length of stay of up to 40 days. It is important that the substrate is constantly stirred/moving to avoid precipitation and to extract as much gas as possible. Some gas is produced after the substrate reaches the final storage if it is not cooled down. An alternative is to capture and lead gas in a "reservoir" to the gas storage.

The bioresidue formed through the biogas process becomes thinner, and the nutrients, especially nitrogen, become more readily available to plants. Nutrients can also be supplied via other substrates that are mixed with animal manure. This makes bioresidue a valuable organic fertilizer.

Climate benefit

Biogas from livestock manure is one of the measures that can really mean a lot if agriculture is to reduce its climate footprint. The biggest effect is that methane loss from the storage of manure, which would otherwise be released into the atmosphere, is taken care of and burned in one way or another (in a boiler, generator or as fuel). During combustion, CO2 will be released, but we count the effect of this as zero, as this has a biological origin and is tied up again in the next season it is grown for the animals. Methane is considered to have 25 times the climate impact of CO2. In the climate game, we have set that the saved CO2 footprint in relation to losses from manure storage is 55% with biogas in relation to traditional operation.

In addition, the use of the biogas for heat, fuel and electricity production will be able to replace fossil energy. In the climate game, we have calculated the total possible methane production and converted it into kWh. We have then used 25% of this as electricity produced and 16% as net heat produced. The rest is losses in the plant, losses in the exhaust and heat that goes into starting the process.

Some consider the fertilizing effect of bioresidue to be greater than using livestock manure directly. In this way, saved commercial fertilizers can also be calculated in the climate accounting.

The efficiency of the biogas plant and the climate effect depend on factors such as residence time in the reactor, leaks, cooling or other treatment of bioresidue.

As with other types of heating systems, we have to calculate a footprint to produce the necessary equipment.

Current raw material, energy content and properties

In agriculture, manure is the most common substrate. The feed given to livestock is significantly broken down in digestion. The energy in a raw material for biogas comes from the dry matter. Most types of manure have a high moisture content, and therefore have a low energy content per volume.

Example of energy potential in animal manure:

Cattle, 8.5 % TS approx. 130 kWh per tonne

Pig, 8 % TS approx. 150 kWh per ton

Chicken, 70 % TS approx. 1000 kWh per ton

(Max 20 % chicken manure)

The energy content of the gas is measured in kilowatt hours, kWh.

Biogas production increases considerably if you have access to other substrates in addition to animal manure. Food waste, fish sludge and slaughter waste are substrates that have a much higher energy content than animal manure.

Example of possible energy potential in other substrates:

Sorted food waste from large households, 13 % TS approx. 750 kWh per ton

Slaughter waste, soft parts, 30% TS approx. 1950 kWh per ton

Fishing sludge, 20% TS approx. 1000 kWh per ton

Such substrates must be sanitized before they are taken into the farm, to avoid the risk of the spread of diseases. There are separate regulations for the treatment of substrates that are brought in to the facility and for the use of bioresidue from these.

Applications for biogas

- Heat production

The biogas produced in a biogas plant can be burned in a gas burner, and used to heat water that is to be fed into a water-borne heating system. The heat can be used to heat residential houses, workshops and livestock buildings on the farm.

- Production of electric current

The biogas is also used to power an internal combustion engine that can be connected to a power generator. Such a unit in a biogas plant is called CHP, "combined heat and power". The electricity produced can be used on the farm, and it is also important to collect the heat from the engine and use it to heat adjacent buildings.

- Upgrading the biogas into fuel

The biogas can be used for motor fuel, thus replacing fossil fuel. The biogas must be cleaned before it can be used as fuel. The methane content in the gas must be at least 98 % before it can be used as fuel. Usually, the gas is cleaned in larger treatment plants linked to large joint biogas plants. As of today, it is not profitable to build treatment plants linked to biogas plants on farms.

What is bioresidue, and how can it be best utilized in agriculture?

Biogas is the residual product from biogas production in a biogas plant, and can be based on animal manure and other substrates such as e.g. food waste and slaughter waste. Bioresidue is homogeneous and thin, and can be used as organic fertilizer for surface spreading and soiling. When spread on the surface, the bioresidue is infiltrated into the soil more quickly than ordinary soft fertiliser. Biorest is high-quality organic fertiliser, and contains the most important nutrients that plants need. Bioresidue can contain up to 4.5 kg N, 0.5 kg P and 2 kg K per m3 of fertilizer. The nutrient content will vary depending on which substrates are used in the plant. Most of the nitrogen is in ammonium form, NH4+, which in the soil is quickly converted to nitrate, NO3-. This is quickly absorbed by the plants. Biorest smells less after spreading than ordinary wet fertiliser.

Watch videos on the topic

From cow poo to electricity from forskning.no

Tasks

What is meant by biogas?

Agriculture accounts for a large proportion of methane gas emissions in the country. Where does this gas come from?

What can be done to reduce methane emissions from agriculture?