The greenhouse was built and put into use in 2007. It has a total floor area of 3,000 m2. Half of the area is used for plant production. The rest of the area consists of a construction hall, designed for the landscape gardeners, as well as common rooms such as changing rooms, sanitary facilities, classrooms and a separate processing room.

Here, tomatoes are grown on 1/3 of the area. There are an average of 1.5 new plants set out each year, and the plants that are set out are raised in the greenhouse. The tomato crop is now at 70 tonnes per year. year. The rest of the area used for cultivation is used for flower production.

Energy consumption

There is an annual consumption of electricity of 1.1 GWh (1.1 million kWh). Tomato production in particular is dependent on a lot of light all year round. Furthermore, around 800,000 kWh of heat energy is used a year to keep production in the greenhouse going. Most of this energy comes from the heat storage installed in the greenhouse.

How does the thermal storage work?

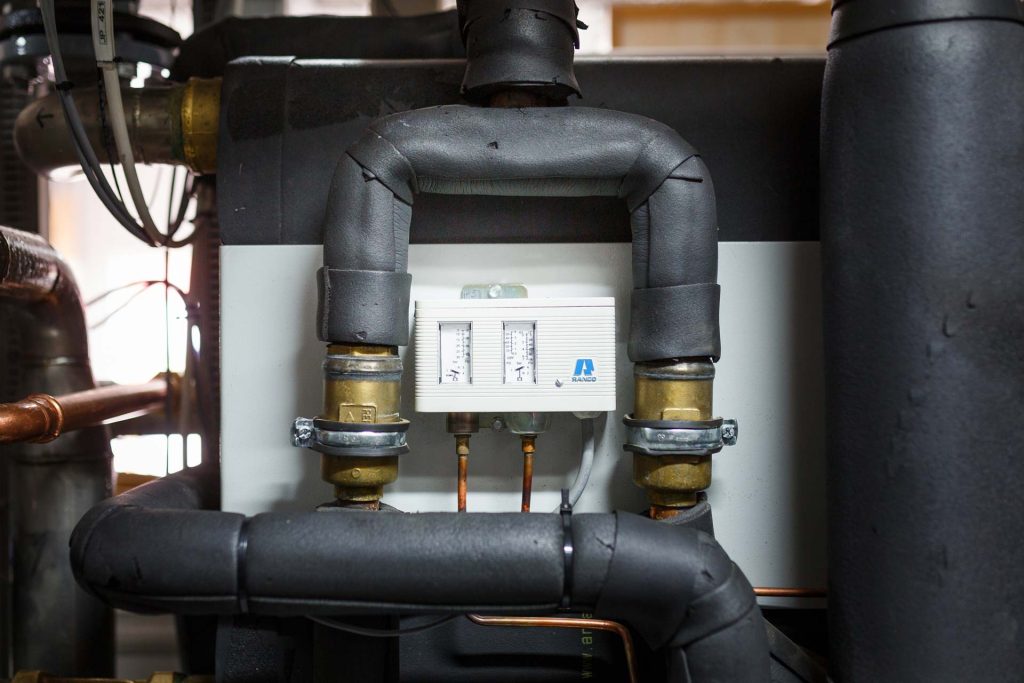

In the greenhouse, an advanced system has been built to take care of heat energy created by solar heat and light in the greenhouse. In the roof of the greenhouse, aerotempers have been installed which, through cooling and dehumidification of the air, make it possible to take care of the excess energy. The energy is stored underground in a large water tank (short-term storage). When the water in this storage has reached a certain temperature, the heat is led further down into deep boreholes outside the greenhouse (long-term storage). There are a total of 44 boreholes in which the heat energy can be stored. The heat is taken out in the cold season, and the effect is increased by using heat pumps. Annually, the heat storage provides a net delivery of more than 900,000 kWh of heat energy. The use of propane for heating has fallen sharply since the thermal storage was put into use. The heat from the heat storage is used to heat the greenhouse, as well as classrooms, offices and other common rooms at the school. Heating pipes have been laid in the ground which transport the heat around the school grounds.

The heat storage has been developed by researchers at Gether AS in collaboration with Trøndelag County Council, SINTEF, Kværner and the school.